Introduction to Semi Truck Blind Spots

If you drive Europe’s corridors—A1s, E-routes, Alpine passes—you already share the road with articulated HGVs every day. The hardest truth is simple: truck blind spots are bigger than most drivers realize, and misjudging them is one of the quietest ways to end up in a preventable crash. This guide, written for dispatchers, professional drivers and everyday motorists, breaks down where the “no-see” areas are, why they exist, and how to keep everyone safer around heavy vehicles.

Introduction to Semi Truck Blind Spots

Definition and Importance

Blind spots are areas around an HGV that the driver cannot see directly or indirectly with mirrors/cameras. Even with great truck driver visibility, cabs sit high, the A-pillars are thick, and the trailer blocks the rear view. Knowing where commercial vehicle blind spots lurk is foundational road safety and truck accident prevention—for the trucker and for anyone driving around trucks.

Common Misconceptions

- “If I can see the driver, they can see me.” Not always—sun glare, rain spray, and mirror vibration degrade sightlines.

- “New trucks have cameras, so it’s fine.” Active blind-spot systems help, but they don’t erase physics. GSR2 phases are still rolling in, and fleets retrofit unevenly across the EU.

Identifying Semi Truck Blind Spots

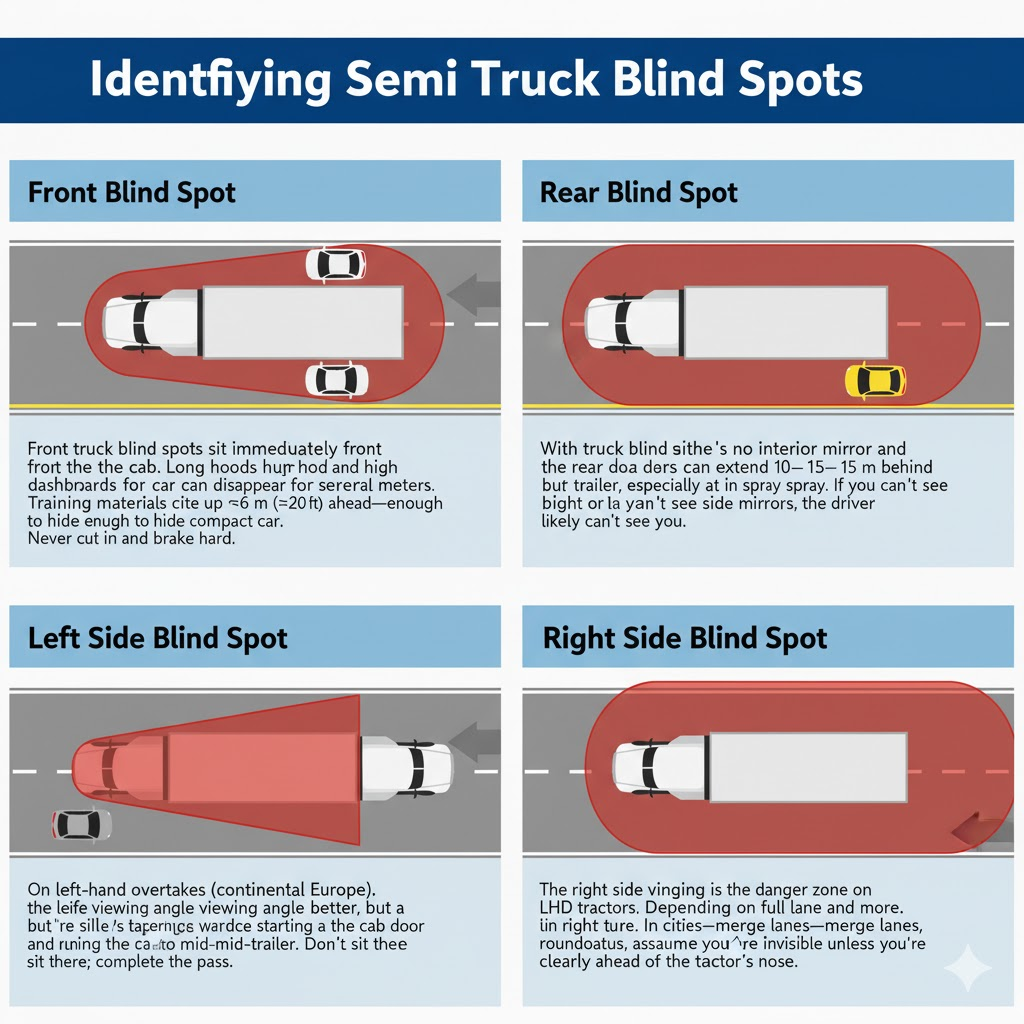

Front Blind Spot

Front truck blind spots sit immediately in front of the cab. Long hoods and high dashboards mean a car or cyclist can disappear for several meters. Training materials cite up to ~6 m (≈20 ft) ahead as “no-see” space—enough to hide a compact car. Never cut in and brake hard.

Rear Blind Spot

With a trailer, there’s no interior mirror and the rear door is a wall. Rear blind spot areas can extend 10–15 m behind the trailer, especially at night or in spray. If you can’t see side mirrors, the driver likely can’t see you.

Left Side Blind Spot

On left-hand overtakes (continental Europe), the left side viewing angle is better than the right, but there’s still a tapering wedge starting at the cab door and running along mid-trailer. Don’t sit there; complete the pass.

Right Side Blind Spot

The right side viewing angle is the danger zone on LHD tractors. Depending on mirror setup, it can span a full lane and more. In cities—merge lanes, roundabouts, and right turns—assume you’re invisible unless you’re clearly ahead of the tractor’s nose.

The “No-Zone” map (typical, LHD tractors)

| Zone (nickname) | Where it sits | What it means for you |

| Front “No-Zone” | ~0–6 m ahead of bumper | Don’t pull in and brake; build a cushion before merging back. |

| Right-side “No-Zone” | Curbside, often ≥1 lane wide | Avoid lingering; if you must pass on the right (rare/illegal in many places), do it decisively and safely. |

| Left-side wedge | From driver door to mid-trailer | Finish the overtake—don’t hover beside the drive axle. |

| Rear “No-Zone” | 10–15 m behind the doors | Leave space; tailgating erases your escape routes. |

Terminology varies. In North America it’s popularized as “no zones” or truck no zones; the physics are universal.

Safe Driving Practices Around Semi Trucks

Maintaining Safe Distances

Leaving time and space is the cheapest insurance in traffic. As a baseline passing distance guidelines reminder: keep at least a 3–4 second gap behind an HGV in the dry; add more in rain or if spray reduces cab to road visibility. Many fleet advisories note that trucks can need significantly more stopping distance than cars; don’t steal their safety margin by cutting in tight.

Proper Passing Techniques

- Signal early, check mirrors twice, and pass with a clear speed differential.

- Return only once you can see both truck headlights in your mirror—then add two car lengths.

- Night or crosswinds? Expect buffeting as you pass the trailer’s midpoint—one of several truck driving hazards that nudge cars back toward the trailer.

Recognizing and Avoiding No Zones

No zone awareness is a habit: if you can’t see the driver’s mirrors or camera pods, assume the driver can’t see you. When road sharing with trucks, either commit to the pass or drop back into clear sightlines. This is the essence of truck blind spot safety and everyday truck safety tips.

Legal Implications and Responsibilities

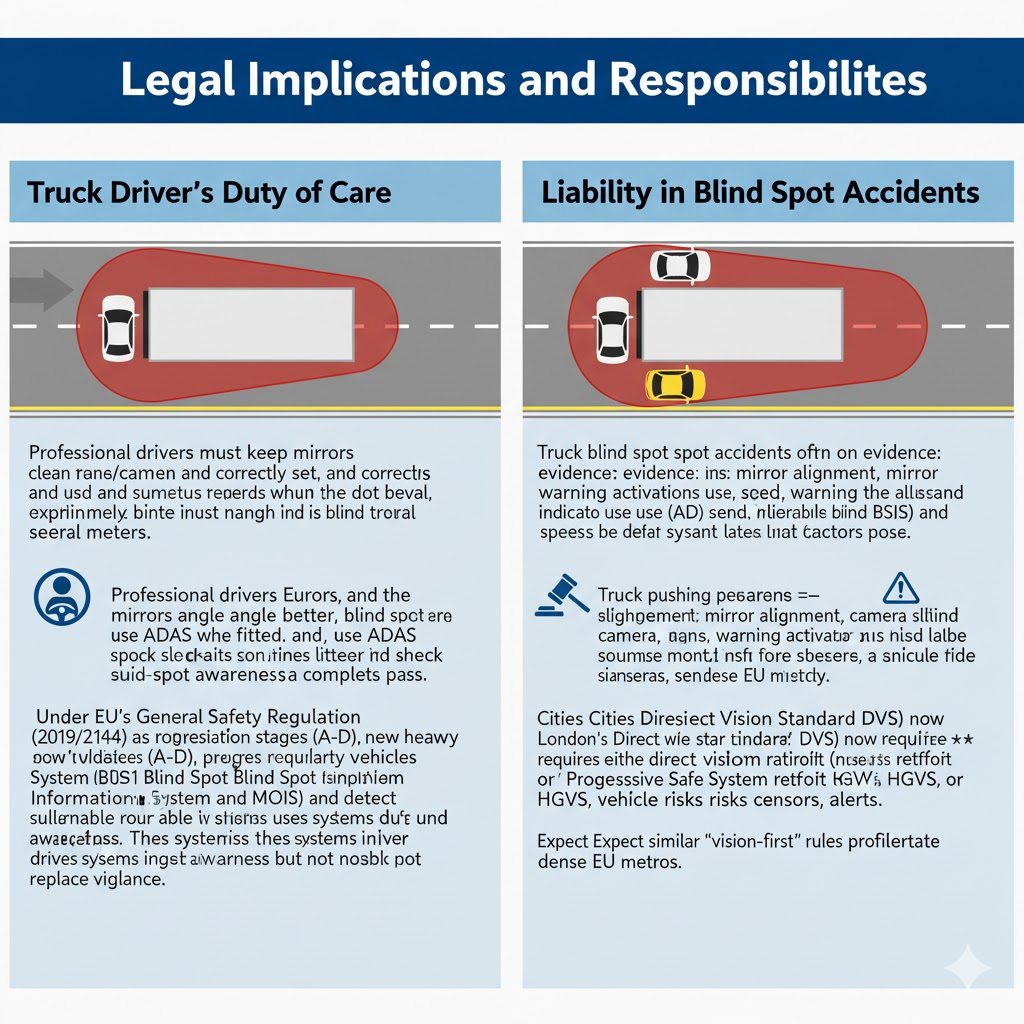

Truck Driver’s Duty of Care

Professional drivers must keep mirrors/cameras clean and correctly set, maintain a blind spot check routine, and use ADAS where fitted. Under the EU’s General Safety Regulation (2019/2144) as rolled out in stages (A-D), new heavy vehicles are progressively required to include a Blind Spot Information System (BSIS) and Moving Off Information System (MOIS) to detect vulnerable road users. These systems increase driver blind spot awareness but do not replace vigilance.

Liability in Blind Spot Accidents

Truck blind spot accidents often turn on evidence: mirror alignment, camera coverage, warning activations, indicator use, and speed. Cities are pushing higher bars: London’s Direct Vision Standard (DVS) now requires either a three-star direct vision rating or a Progressive Safe System retrofit (near-side cameras, sensors, alerts) for HGVs, or the vehicle risks penalties. Expect similar “vision-first” rules to proliferate in dense EU metros.

Mirror Alignment Tips (Table You Can Hand to a Yard Marshal)

Proper setup shrinks truck blind spot zones before the wheels turn. The DEKRA method below works for common EU mirror packs (main, wide-angle, kerb/front):

| Mirror | Target view at rest | Why it matters | Field checklist |

| Main (flat) – driver side | Trailer edge barely inboard; horizon centered | Accurate distance/closing speed | Seat set → mirror set. Check daily. |

| Wide-angle – driver side | Vehicle flank just in frame | Captures cars lingering by the drive axle | Align so the vehicle edge kisses the guide line. |

| Kerb/aux – passenger side | Curb & lower trailer flank visible | Critical for cyclists/pedestrians | Clean lens after every fuel stop. |

| Front/kerb mirror | Area immediately in front of bumper | Eliminates close-in obstacles at lights | Re-set after any service hit. |

Source synthesis from DEKRA’s step-by-step mirror guide; adapt to your tractor’s mirror generations and camera replacements.

Insider tip: Add “wipe & set” to your visibility maintenance tips—mirrors/cameras/lidar get coated with winter salt and summer bugs. A 30-second wipe can be the difference between catching a scooter or missing it entirely.

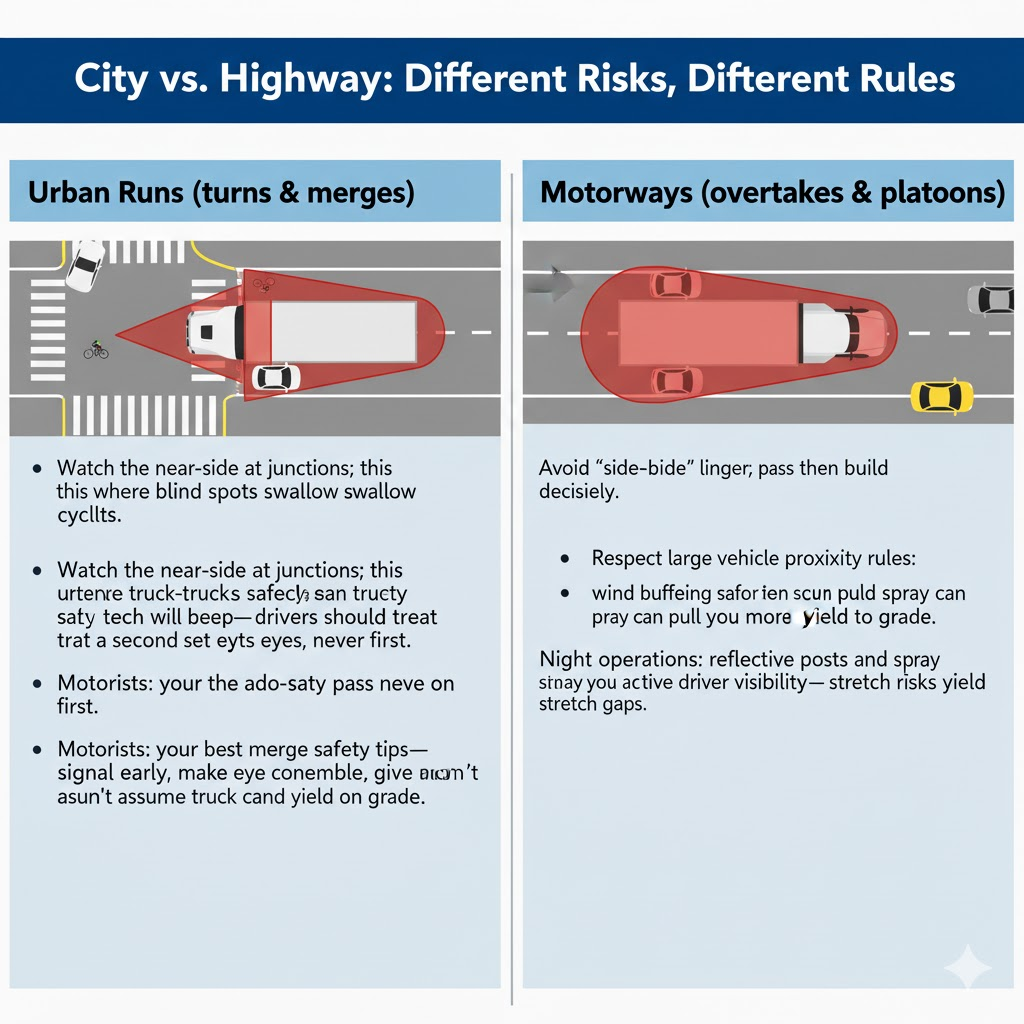

City vs. Highway: Different Risks, Different Rules

Urban Runs (turns & merges)

- Watch the near-side at junctions; this is where truck driver blind spots swallow cyclists.

- In DVS cities, new semi-truck safety tech will beep or flash—drivers should treat alerts like a second set of eyes, never the first.

- Motorists: your best merge safety tips—signal early, make eye contact when possible, and don’t assume the truck can yield on a grade.

Motorways (overtakes & platoons)

- Avoid “side-by-side” linger; pass decisively, then build space.

- Respect large vehicle proximity rules: wind buffeting and spray can pull you in; give more margin than you would around a car.

- Night operations: reflective posts and spray halve effective truck driver visibility—stretch gaps.

Inside the Cab: How Pros Shrink Blind Spots

The best fleets systematize safe driving practices so they’re muscle memory:

- Walk-around: lamps, lenses, sensors, mirrors—anything that affects cab to road visibility.

- Seat-then-mirror: adjust seating first; then set mirrors/cameras to the body, not the other way.

- Blind-spot cameras: confirm views for the near-side and front; wipe lens if needed.

- Indicator discipline: three flashes before moving laterally; check again mid-maneuver.

- Speed discipline: your biggest ally in truck accident prevention is time.

- Situational scan: refresh every 8–10 seconds—mirrors, cluster, mirrors. That’s your blind spot check routine.

Fresh compliance note: Under the EU GSR2 timeline, more N2/N3 vehicles registered after 7 July 2024 include BSIS/MOIS by design. Expect the remainder to filter in by 2026/2029 stage gates as models refresh. Ops managers: map your fleet’s compliance by VIN year and body style.

Passing and Merging: A Driver-Ready Quick Table

| Situation | Your move | Why it works |

| You’re behind an HGV on a dual carriageway | Build a 3–4 s gap, then overtake with a speed delta ≥10 km/h | You exit the side wedge quickly and keep shockwaves predictable. |

| Returning to lane after passing | Don’t cut in until both headlights fill your mirror, then add space | Preserves the truck’s stopping margin; avoids the front truck blind spots pocket. |

| Truck indicates a lane change toward you | Flash, lift off, fall back out of the wedge | Makes yourself visible and gives the driver room to complete. |

| Truck is reversing to a bay | Stop outside the rear blind spot areas; wait for hand signals | Reversing cameras don’t cover everything; dock glare is real. |

| Busy roundabout in the rain | Stay out of the near-side; do not share the lane beside the trailer | Spray + angle = zero truck driver visibility on the curb side. |

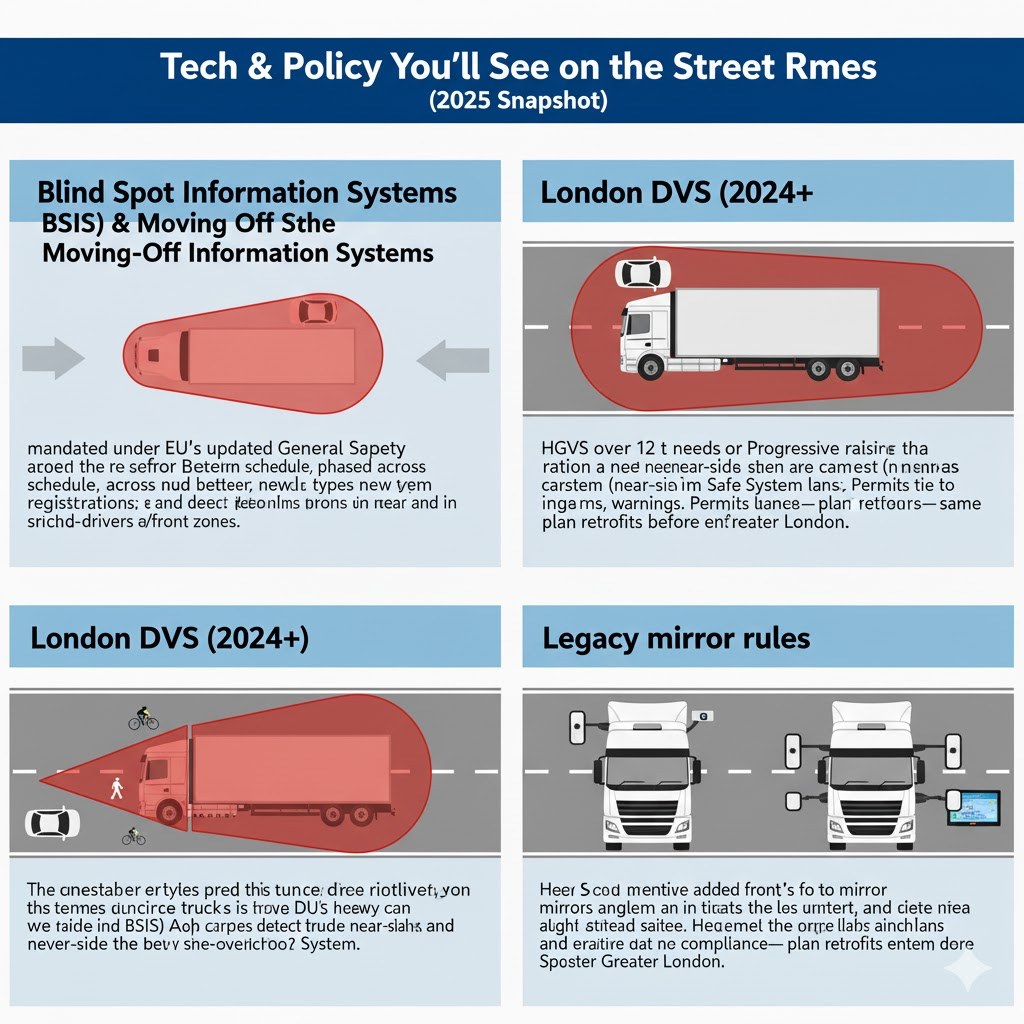

Tech & Policy You’ll See on the Street (2025 Snapshot)

- Blind Spot Information Systems (BSIS) & Moving-Off Information Systems (MOIS): mandated under the EU’s updated General Safety Regulation schedule, phased across new types and registrations; designed to detect pedestrians and cyclists in near-side/front zones.

- London DVS (2024+): HGVs over 12 t need a star rating or a Progressive Safe System (near-side camera, sensors, warnings). Permits tie to compliance—plan retrofits before entering Greater London.

- Legacy mirror rules: Older EU directives added front/kerb mirrors to cut blind spots; newer fleets may replace some mirrors with digital camera monitors—same responsibility, sharper images.

Why Blind Spot Culture Works (Data Angle)

EU monitoring shows heavy goods vehicles remain over-represented in fatal collisions with pedestrians/cyclists in urban areas, even as overall fatalities fall. The fix is cultural as much as technical: disciplined habits, better infrastructure and vehicles that improve cab to road visibility at the source.

Conclusion

Recap of Key Points

- Know the map: front, right-side, left-side, and rear are the primary truck blind spot zones.

- Space is safety: distance and decisive passes are your best truck safety tips.

- Tech helps, habits win: BSIS/MOIS and DVS retrofits add layers, but checks and patience beat gadgets.

- Everyone has a role: motorists, cyclists and truckers alike carry shared responsibility in truck blind spot safety.

Final Safety Reminders

Think in margins, not milliseconds. Build the gap, finish the pass, avoid hovering in wedges, and assume nothing about what a driver can see. That mindset, coupled with mirror alignment tips, visibility maintenance tips, and modern ADAS, is how we lower the temperature on Europe’s busiest roads.

Compliance & Sources (selected)

- EU General Safety Regulation (2019/2144) – safety tech mandates, including BSIS/MOIS; staged timeline for new types/registrations.

- TfL Direct Vision Standard (DVS) – permits, star ratings, Progressive Safe System (near-side cameras/sensors).

- DEKRA mirror setting guide – practical steps to reduce blind spots before departure.

- CVSA “No-Zones” primer – front/side/rear blind spot concepts for large trucks.

- European Road Safety Observatory & ETSC – professional driver safety context and measures to reduce HGV collisions.

No responses yet