Introduction to Runaway Truck Ramps

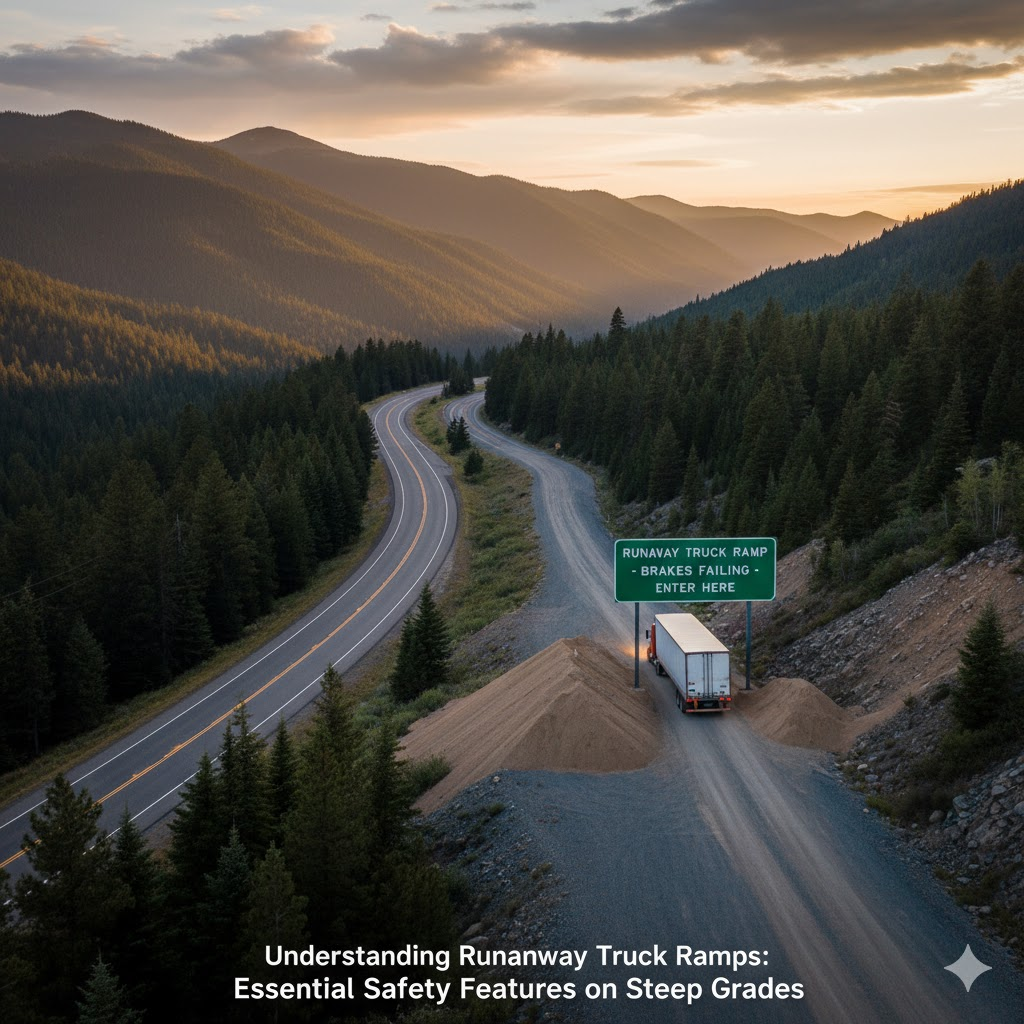

On long Alpine descents and steep highway grades from the Pyrenees to the Carpathians, one safety device quietly saves lives: runaway truck ramps. Built as last-resort lanes for heavy vehicles with overheated or failed brakes, these emergency facilities absorb kinetic energy fast—turning chaos into a controlled stop. In this field guide for dispatchers, trainers, and professional drivers, we unpack ramp types, where they’re placed, how to use them, and the practical standards and maintenance routines that keep them working when seconds count.

Insider context (EUnews24 style): Europe tends to call them escape lanes or vehicle arrester beds. The engineering is universal—gravel resistance, gravity, sand piles, or mechanical nets—but details vary by country. UK’s DMRB carries legacy guidance on vehicle arrester beds; UN ESCAP offers modernized regional design patterns; Caltrans and TRB research provide deep arrester-bed science that many road authorities still reference.

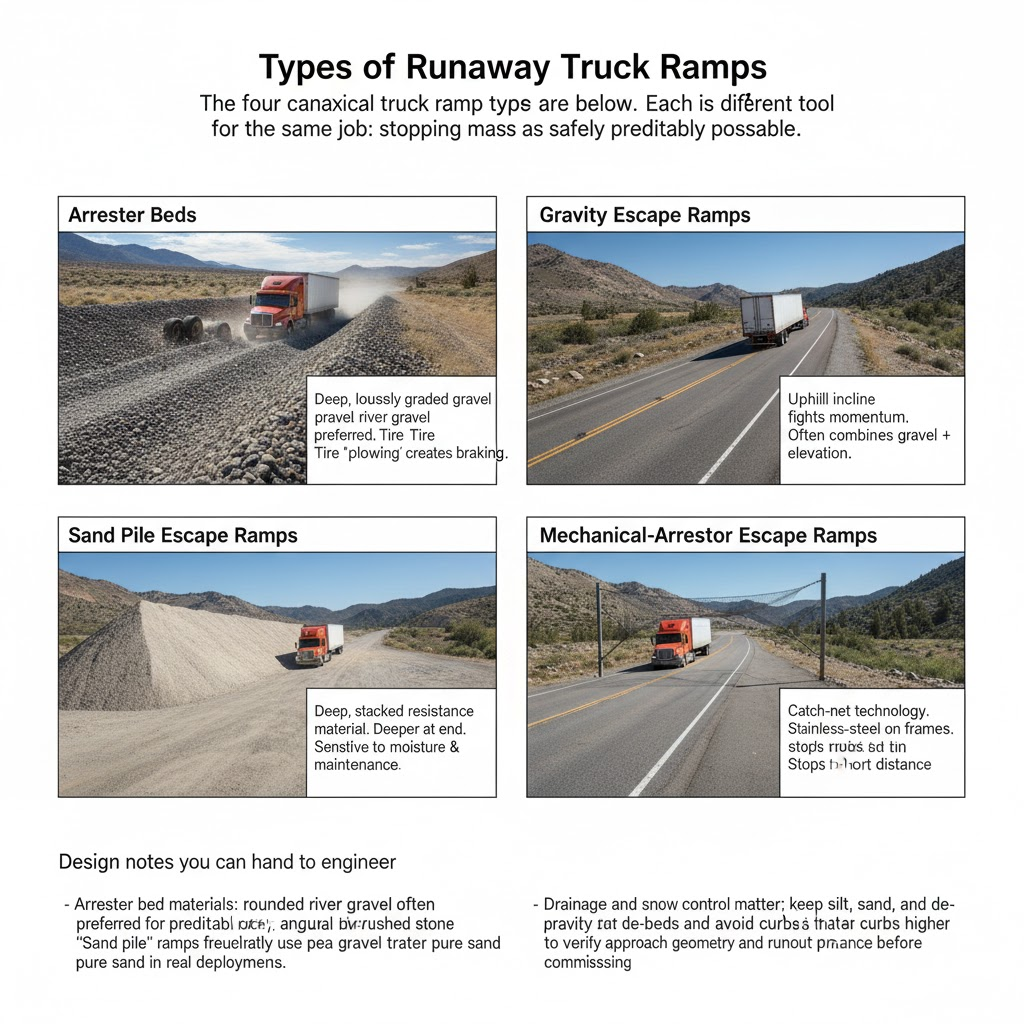

Types of Runaway Truck Ramps

The four canonical truck escape ramp types are below. Each is a different tool for the same job: stopping mass as safely and predictably as possible.

Arrester Beds

An emergency escape ramp with a truck arrester bed uses deep, loosely graded gravel to create huge rolling resistance. Key variables are aggregate size and shape, depth, and length. Field and laboratory studies (Pennsylvania Transportation Institute, TRB) demonstrated why rounded, loose gravel decelerates better than you might expect—tire “plowing” through the bed generates the braking force.

Design notes you can hand to an engineer

- Arrester bed materials: rounded river gravel often preferred for predictable rolling resistance; angular crushed stone can increase drag but may alter steering feel.

- Sand pile depth is not the same as gravel depth; “sand pile” ramps frequently use pea gravel rather than pure sand in real deployments.

- Drainage and snow control matter: keep silt, sand, and de-icer out of beds and avoid curbs higher than ~50 mm that hinder recovery.

Gravity Escape Ramps

A gravity escape ramp points uphill—your momentum fights the incline. When space allows, this is elegant and low-maintenance. Many designs combine a short gravel section plus elevation for redundancy. Research and guidance also reference gravity ramp testing to verify approach geometry and runout performance before commissioning.

Sand Pile Escape Ramps

A sand pile escape ramp (often gravel in practice) stacks high-resistance material deeper toward the end. Simpler to build in constrained corridors, but highly sensitive to material moisture, grading, and ramp maintenance schedule discipline.

Mechanical-Arrestor Escape Ramps

A mechanical-arrestor escape ramp uses catch-net technology—stainless-steel nets on frames that “pay out” energy, stopping a truck in far less distance and sometimes on flat or downhill alignments. These systems require rigorous installation tolerances and periodic mechanical arrestor test routines after activations.

Types at a Glance (Operator Table)

| Feature | Arrester bed | Gravity escape ramp | Sand pile escape ramp | Mechanical-arrestor escape ramp |

| Primary stopping mechanism | Rolling resistance in deep gravel | Elevation (uphill grade) + friction | Deepening loose material (often pea gravel) | Energy-absorbing nets/cables |

| Space needed | Moderate–high (length for speed/mass) | High (needs uphill length) | Moderate (depth at end) | Low–moderate (short footprint) |

| Maintenance load | Medium (material grooming, friction surface checks) | Low–medium | Medium–high (material moisture/compaction) | High (inspection after every use) |

| Best use case | Mountain passes with space | Where long steep highway grades end near open terrain | Constrained corridors needing short runout | Tight corridors, flat or downhill runaway truck ramp location |

| Typical standards/guides | DMRB/UN ESCAP/TRB/FHWA | Same + grade modeling | Same | Vendor specs + road authority approvals |

Guidance landscape: DMRB TD 19/06 (legacy), UN ESCAP highway design guides, Caltrans design guide, TRB syntheses & field studies. Always align with national runaway truck ramp standards and ramp installation standards in your jurisdiction.

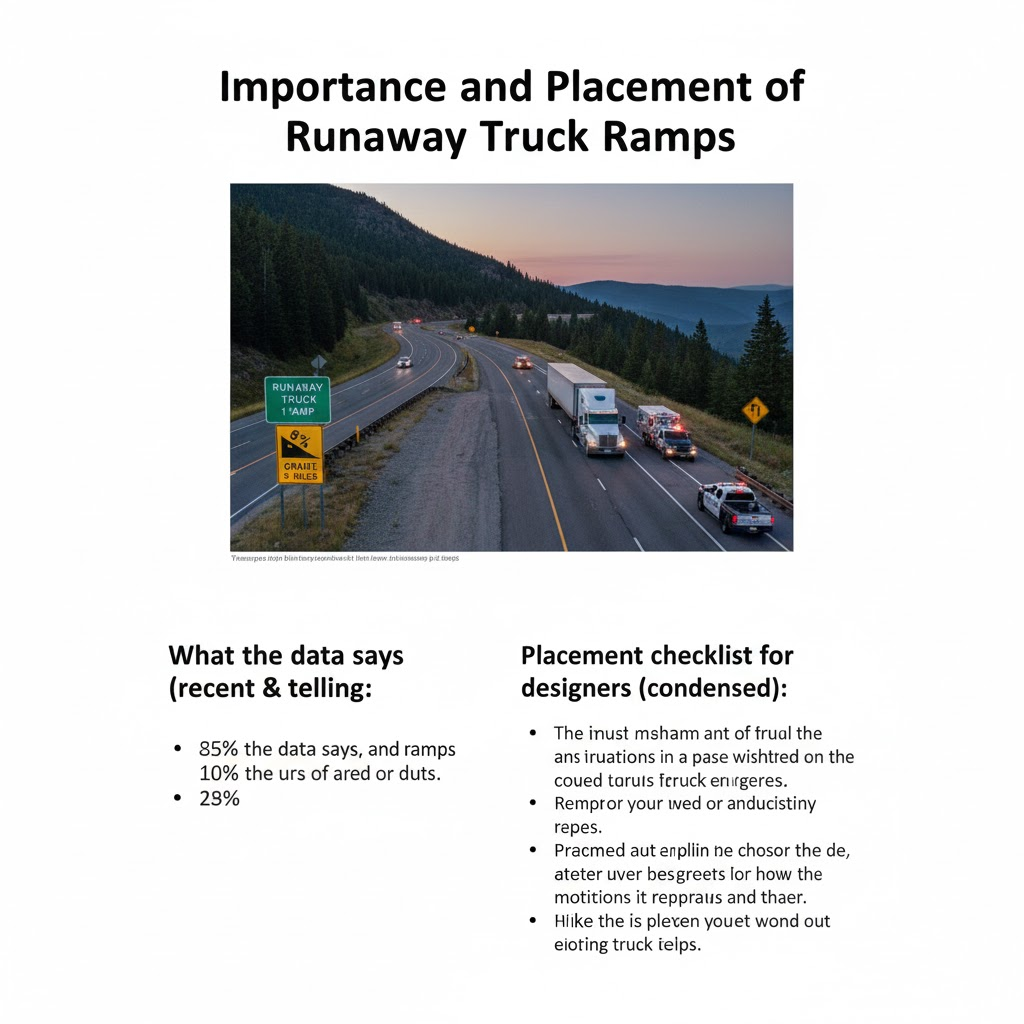

Importance and Placement of Runaway Truck Ramps

Where do these facilities go? Planners perform runaway risk assessment on corridors with frequent brake fade and downhill runout risk—long descents followed by tight curves, tunnels, toll plazas, or urban fringes. Ramps appear before critical curvature or stop points, with geometry that allows a clear, instinctive entry from the slow lane. Caltrans, TRB, and UK/European guidance emphasize sight distance, exit ramp accessibility, and recovery logistics (tow access, emergency vehicle access) in the runaway truck ramp design phase.

What the data says (recent & telling):

- Colorado DOT recorded 30 uses in 2020, 32 in 2021, 44 in 2022, and 31 by late-2023—evidence that runaway truck ramp usage is not rare on major grades like I-70.

- Historic TRB synthesis estimated thousands of truck runaway incidents per year in the U.S.; trucks that didn’t use ramps were linked to the vast majority of damage costs—underscoring runaway truck ramp effectiveness when drivers commit to them.

Placement checklist for designers (condensed):

- Runaway truck ramp location: near the bottom third of a critical downgrade, ahead of grade transition zones or chokepoints.

- Incline warning devices: conspicuous percent-grade + distance signs well in advance; repeaters after each major curve.

- Runaway truck ramp signs: big, bilingual where needed, with distance countdown tablets; reflective ramp signs and ramp lighting needs assessed for night/fog/snow.

- Road safety infrastructure: guardrail transitions that guide, not block, ramp entry; ramp construction quality and approach alignment verified by survey.

- Runaway truck ramp installation planning includes incident reporting protocol and emergency response readiness with local services.

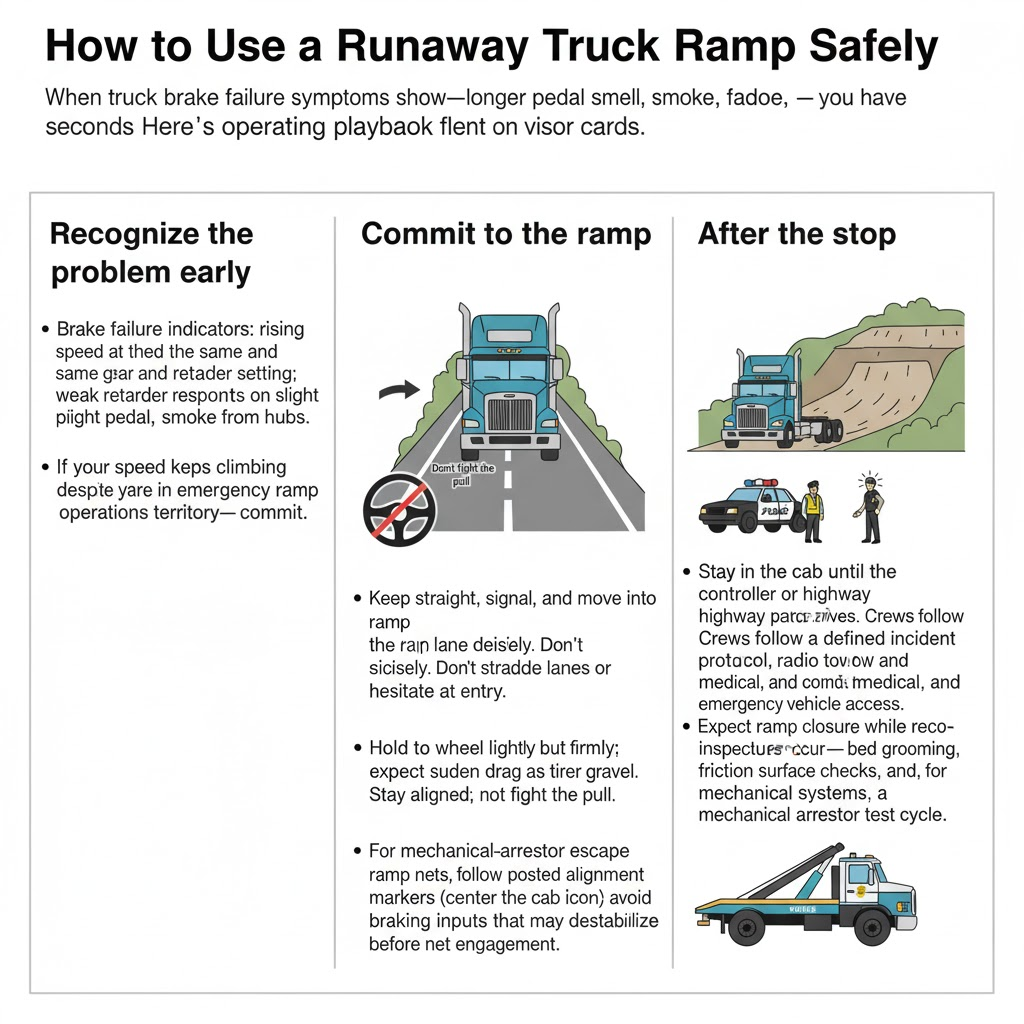

How to Use a Runaway Truck Ramp Safely

When truck brake failure symptoms show up—longer pedal travel, burning smell, smoke, fade—you have seconds to choose. Here’s the operating playbook fleets print on visor cards.

Recognize the problem early

- Brake failure indicators: rising speed at the same gear and retarder setting; weak retarder response; ABS events on slight pedal; smoke from hubs.

- If your speed keeps climbing despite engine braking, you are in emergency ramp operations territory—commit.

Commit to the ramp

- Keep straight, signal, and move into the ramp lane decisively. Don’t straddle lanes or hesitate at entry.

- Hold the wheel lightly but firmly; expect sudden drag as tires enter gravel. Stay aligned; do not fight the pull.

- For mechanical-arrestor escape ramp nets, follow posted alignment markers (center the cab icon); avoid braking inputs that may destabilize before the net engagement.

After the stop

- Stay in the cab until the controller or highway patrol arrives. Crews follow a defined incident reporting protocol, radio tow and medical, and coordinate emergency vehicle access.

- Expect ramp closure while recovery and ramp inspection procedures occur—bed grooming, friction surface checks, and, for mechanical systems, a mechanical arrestor test cycle.

Training, Prevention & Responsibility

Ramps are the last line. The first line is truck runaway prevention—smart driving, maintenance, and route planning.

Driver training programs (what good fleets teach)

- Downhill gear selection: Never rely on service brakes alone; use engine brake and retarder to hold speed.

- Speed policy on steep highway grades: Set lower maxima for weight/hazardous cargo; enforce with telematics.

- Blind-spot habit for signs: Build no-hesitation comfort with runaway truck ramp signs and entry protocols via simulator drills and hill-pass ride-alongs.

- Winter specifics: wet compacts bed material; expect softer entry and longer plowing distance—briefed in driver training programs.

- Truck runaway prevention measures pre-descent: brake temp check, hub scan, brake line diagnostics, and stop for cool-down if thresholds are exceeded.

Vehicle runaway prevention (shop & yard)

- PMs aimed at vehicle runaway prevention: verify lining thickness, drum/disc condition, retarder operation; pressure and leak checks; grade transition zones heat-soak behavior in dyno testing for hill fleets.

- Tire and hub downhill runout risk checks before known passes.

Maintenance & Inspection (Operator Tables You Can Use)

A. Ramp Maintenance Schedule (field template)

| Task | Frequency | Why it matters |

| Bed raking/leveling | After each activation + weekly in high season | Restores uniform resistance and approach profile (arrester bed). |

| Material top-up & grading | Monthly/seasonal | Keeps sand pile depth / gravel depth to spec; prevents ruts. |

| Drainage & silt removal | Pre-winter + post-storms | Prevents saturation that slashes resistance; preserves ramp construction quality. |

| Sign visibility maintenance | Monthly + after storms | Replace damaged reflective ramp signs; trim foliage; night retro-reflectivity checks. |

| Lighting & power | Quarterly | Ramp lighting needs for night/fog; test circuits and backup. |

| Mechanical net inspection | After each use | Structural checks + mechanical arrestor test; reset nets per manufacturer. |

| Documentation | After any intervention | Log ramp survey data, activation notes, and ramp installation standards compliance. |

B. Arrester Bed Design Considerations (for design reviews)

| Parameter | Typical consideration | Field note |

| Aggregate gradation | Rounded 16–32 mm common for car tests; heavier trucks require modeled lengths | Rounded river gravel shows consistent drag; check local availability. |

| Bed depth & length | Function of entry speed, mass, grade, coefficient of rolling resistance | Use TRB/FHWA calculators or validated worksheets. |

| Approach & alignment | Straight approach from slow lane; forgiving shoulders | Avoid high curbs; Caltrans flags ≤ 2 in (≈50 mm). |

| Recovery plan | Tow staging & emergency vehicle access | Plan winch angles that don’t disturb bed geometry. |

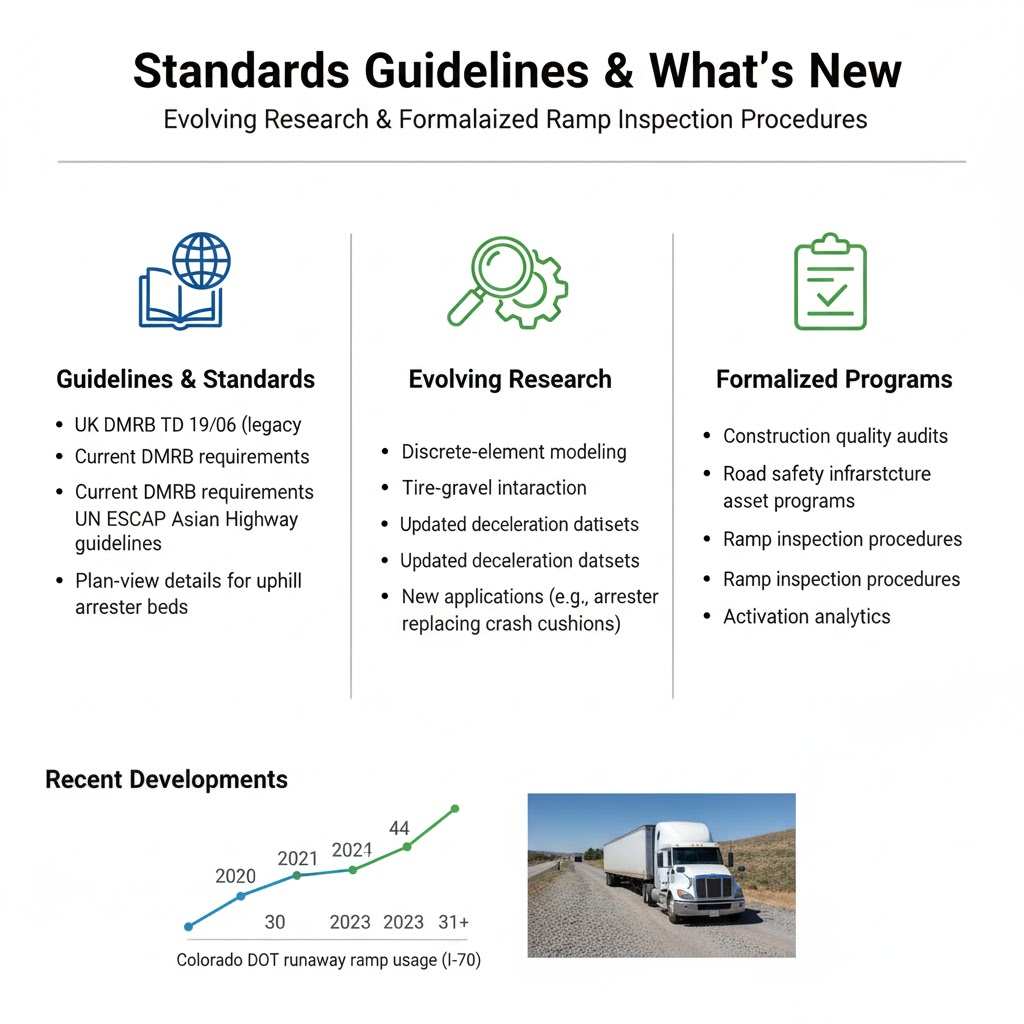

Standards, Guidelines & What’s New

- Runaway truck ramp guidelines / standards: UK’s now-legacy DMRB TD 19/06 chapter on vehicle arrester beds is widely cited; the online DMRB hosts current requirements and advice documents. UN ESCAP’s Asian Highway guidelines include plan-view details for slip-road escape lanes with uphill arrester beds.

- Runaway truck ramp design considerations keep evolving with research: discrete-element modeling of tire–gravel interaction, updated deceleration datasets, and new applications (e.g., arrester beds replacing crash cushions in some motorway settings).

- Runaway truck ramp installation and ramp construction quality audits are trending more formal—authorities are folding ramps into broader road safety infrastructure asset programs with ramp inspection procedures and activation analytics.

Effectiveness & statistics you can quote

- TRB synthesis: when ramps are used, damages are vastly lower than when they’re missed or unavailable—supporting investment in highway safety measures at known grades.

- Recent corridor data: I-70 Colorado shows dozens of activations per year; agencies report shorter closures as recovery and maintenance workflows improve. Good evidence for runaway truck ramp effectiveness and disciplined post-use procedures.

Driver-Facing Quick Guide (printable)

Before the hill (prevention)

- Incline warning devices ahead? Downshift early.

- Confirm retarder mode, cooling, hub temps.

- If something feels off, delay descent—vehicle runaway prevention beats heroics.

On the hill (decision window)

- Rising speed despite engine braking = brake failure indicators.

- Scan for runaway truck ramp signs and prepare to commit.

Using the ramp (execution)

- Signal, hold lane, enter square. Expect steering “float” on gravel; keep it straight.

- For nets: follow alignment markers; hands steady; no last-second swerves.

- After stop: hazards on, remain in cab; wait for emergency response readiness crew.

Where EU Ops Meet Real Roads (Placement Examples)

- Mountain passes & tunnels: Escape lanes often sit before tunnel portals or tight valley curves—prime runaway truck ramp location choices where downhill runout risk meets constrained terrain. European “forgiving roadsides” doctrine explicitly lists arrester beds as a mitigation in diverge areas on steep links.

- Urban peripheries: If a descent feeds a toll plaza or signalized junction, designers prioritize short-footprint solutions or parallel ramps with fast emergency vehicle access.

Operations After an Activation (What Dispatch Should Expect)

- Emergency ramp operations kick in: patrol arrives, cordons the site, checks driver, calls wrecker.

- Incident reporting protocol: time, weather, vehicle specs, weight, entry speed (if telematics), bed condition, and any injuries.

- Ramp maintenance schedule: groom, top-up, drainage sweep, signage and ramp lighting needs test, friction surface checks, and documentation.

- Maintenance crew training makes or breaks readiness. Authorities run recurring modules on bed shaping, moisture control, and net resets—codified in their O&M manuals.

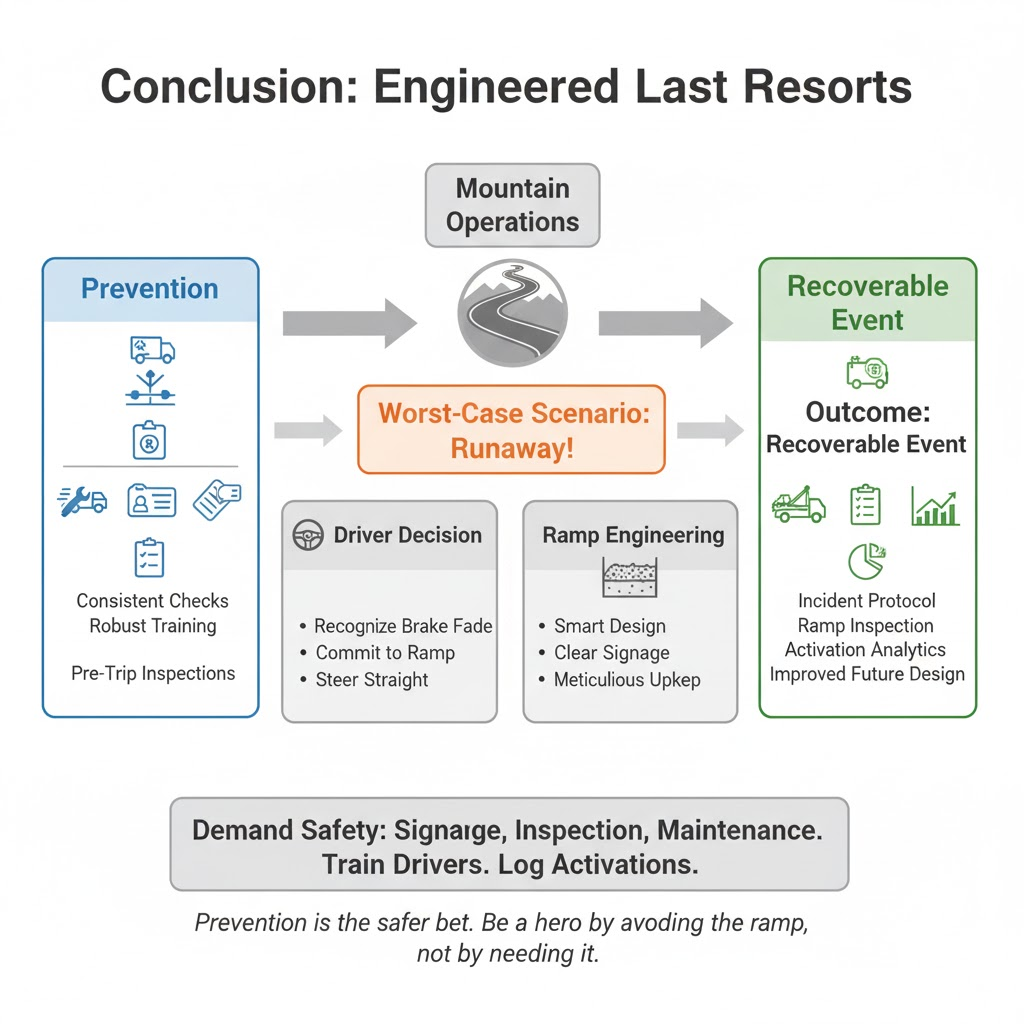

Conclusion

Escape lanes aren’t decorative—they are engineered last resorts that turn worst-case truck runaway incidents into recoverable events. The best results happen when smart runaway truck ramp design meets disciplined driver decisions and meticulous upkeep. Whether you operate in the Alps, Apennines, or across Balkan grades, demand clear signage, reliable ramp inspection procedures, and a living ramp maintenance schedule. Train drivers to recognize brake failure indicators, normalize ramp use, and log every activation so your ramp survey data improves the next design review.

And remember: you only need to be a hero once—on the mountain—if prevention fails. The safer bet is consistent truck runaway prevention, robust driver training programs, and equipment checks that keep truck accident prevention from ever depending on gravel, nets, or gravity.

Appendices & Operator Tables

A) Ramp Design & Installation Snapshot

- Runaway truck ramp installation: verify geotechnical support, bed drainage, and approach sight distance.

- Runaway truck ramp guidelines: align national manuals (DMRB/UN ESCAP/Caltrans) with site constraints; log deviations and mitigations.

- Truck ramp construction & ramp construction quality: QC aggregate gradation, bed depth, compaction at approaches, and survey finish elevations.

- Runaway truck ramp design considerations: mass/speed envelopes, weather/microclimate, recovery logistics, and ramp lighting needs.

- Runaway truck ramp standards: signage per national traffic signs manuals; check retro-reflectivity, mounting heights, and placement.

B) Placement & Risk Matrix (for corridor studies)

| Factor | Why it matters | Data inputs |

| Highway grade safety profile | Predicts fade probability | % grade, length, curvature, traffic mix |

| Truck runaway risk factors | Weight, brake spec, retarder prevalence | Fleet surveys, enforcement data |

| Runaway crash statistics / truck runaway statistics | Justify funding, design length | Police logs, national databases, CDOT examples |

| Runaway truck ramp location options | Feasibility & entry geometry | ROW, terrain, structures, exit ramp accessibility |

| Runaway truck ramp effectiveness | ROI & safety case | After-action reports, TRB syntheses |

C) Operations QA (what to audit quarterly)

- Reflective ramp signs retro-reflectivity; sign visibility maintenance after foliage growth or winter grime.

- Friction surface checks on paved approaches; ravel or polish affects entry control.

- Bed profile survey vs. design; arrester bed materials top-up if out of tolerance.

- Ramp lighting needs and power redundancy tests.

- Maintenance crew training records and emergency response readiness drills logged with timestamps.

- Ramp installation standards re-verification after major repairs.

- Emergency vehicle access drills with tow operators and fire services.

- Annual runaway risk assessment refresh for any corridor with changing traffic mix or grades.

Sources & Further Reading

- UK DMRB TD 19/06 (legacy): Vehicle Arrester Beds—design & construction guidance.

- UN ESCAP: Detail Design Guidelines (escape ramps layouts and runaway truck ramp guidelines for regional highways).

- Caltrans: Design Guide for Truck Escape Ramps—practical notes on curbs, drainage, recovery.

- TRB/Transportation Research Record: Field Study & Performance papers on gravel arrester beds and energy-absorption mechanics.

- MDPI (2020): Passenger-car deceleration on gravel beds (granularity 16–32 mm)—useful boundary data.

- CEDR: Forgiving Roadsides—arrestor beds at diverges and as part of safety design.

- Colorado usage stats & operations updates (2019–2023): Colorado Sun & Denver7 reports.

- National Academies (2024): Truck Emergency Escape Ramp Design and Operation literature review.

No responses yet